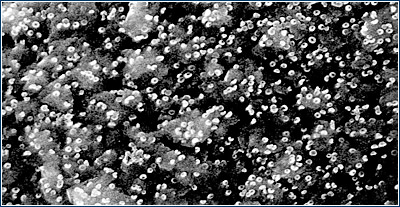

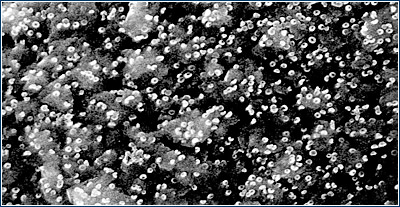

We approach this area as an application of a particular class of sprays, the electrospray, that we have been studying on and off for several years. The unique ability of such a system to generate droplets or particles of narrow size distribution over a phenomenally wide range of sizes, from molecular dimensions to tens of micrometers, can be particularly useful in drug delivery. Specifically, we are interested in targeted or controlled drug release using electrosprayed aerosols. We have developed a technique to electrospray aqueous solutions with optimal size distribution for deposition deep into the lungs (J. Aerosol Sci. 25, pp.1237-1249, 1994). We can also produce ultrafine protein pharmaceuticals by electrostatically spraying suitable protein solutions. For example, we can produce monodisperse insulin particles tens of nanometers in diameter (the white particles in the figure below) without affecting their biological activity. We would like to test the potential of these particles for controlled drug release after their encapsulation in a polymer matrix. We are also investigating opportunities to adapt microfabrication techniques to the multiplexing of these aerosol sources to reach flow rates large enough for commercial applications.

For more information (PDF file).

We are developing a clean and efficient mesoscale combustor for power generation from liquid hydrocarbons. Once it is coupled with a thermal-to-electric energy conversion system, its application would include the replacement of conventional batteries with hydrocarbon based rechargeable ones. The incentive to use combustion for this purpose rests on the high energy density of liquid hydrocarbons, some two orders of magnitude larger than, say, Li-Ion batteries.

Thus, even modestly efficient systems can result in dramatic improvements, with the additional benefit of the ease of recharging the battery by simply replenishing the fuel supply. Difficulties associated with the combustion of even notoriously polluting fuels, such as JP8, are circumvented in our system with a novel combination of fuel electrostatic spraying and catalytic combustion. Dispersion of the liquid fuel and subsequent mixing and vaporization are achieved in a small volume by electrospraying, which, using PCI (Precision Combustion Inc., North Haven, CT) microliths, requires minimal power and no elevated pressures. No significant amount of surface fouling, that is typically observed when the phase change of JP8 takes place near solid surfaces, is detected. Neither soot nor gaseous pollutants, except for a small amount of unburned hydrocarbons, are found in the exhaust gases and almost complete conversion of CO to CO2 is achieved, despite the low combustion temperatures (1200 K) and the relatively short residence times. The output of the burner is a uniformly hot surface at a temperature appropriate for coupling with direct energy conversion modules. Current efforts are focused on further miniaturization of the device using microfabrication approaches.